Product Support

Sand filter pump troubleshooting

Normally this is caused by an electrical issue. Please ensure that the filter pump is plugged directly into the mains socket and not an extension lead. Please check the socket with other items to ensure this is not an issue with the socket itself.

Step 1 – Check control valve

Make sure the control valve is set to correct position.

Step 2 – Check for any blockages

We recommend following this checklist to check for any blockages which may be affecting the water flow through the pump.

Check the debris screens are clean and unblocked

Check the pipes are clean and unblocked

Check hose clamps are attached correctly and are not restricting the water flow

Make sure the stopper plugs have been removed from the pool

Make sure the strainer is clear from debris

Normally this is caused when the item is not regularly cleaned or maintained. Back flush the unit and replace the sand.

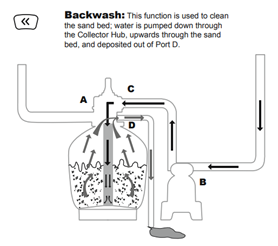

How to back flush:

- Turn power off (important, should not run the pump dry, will cause damage to pump)

- Close Port A using cap (switch from Port D to Port A basically)

- Attach hose to Port D

- Put the control valve to backwash position (<< symbol)

- Turn pump on until water turns clear (or around 3-5 mins)

- Turn pump off once water turns clear

- Remove old sand and refill, or rinse existing sand (water droplet symbol – rinse for 1 min)

- Once complete, remove cap from Port A and apply to Port D

Step 1 – Has the control valve been set between 2 different functions

If this is the case please set the control valve to just 1 function only.

Step 2 – Check if the gasket is broken.

Step 1 – Check if hoses are out of place.

If this is the case please realign any out of place hoses.

Step 2 – Are the adapters attached correctly?

We recommend to check the adapters are securely fastened.

Step 3 – Are the couplings out of place?

Check the positioning and if they are out of place realign couplings.

If the pump casing is leaking this means that the seals are either broken or out of place. Check and realign the seals.

If the pool water is dirty this could be due to blockages stopping the pump from working correctly. We recommend checking the following to resolve this:

Step 1 – Check debris screens are clean and unblocked.

Step 2 – Check running time of pump and increase running time if necessary.

Step 3 – Check your chemical usage.

If you need further chemical advice we recommend using our helpful chemical guide here.

We recommend completing the following steps to diagnose and resolve the issue causing sand to appear in your pool.

Step 1 – Is the sand being used too small?

The recommended is 0.45mm to 0.85mm #20 Silica Sand.

Step 2 – Move the control valve and perform the back flush to the filter function without stopping the sand filter

Turn off power to the Sand Filter (on/off switch on the pump) as changing the setting whilst running can cause damage to the pump; each setting will control the water flow differently.

Step 3 – Is the skimmer broken?

If this is the case we recommend replacing the skimmer.

Step 4 – Check if the level of the sand is too high

Check the level of the sand is between min and max lines

Step 5 – Has a back flush and rising been performed?

If not, perform the back flush and rinsing procedure. This is especially important to do when the sand is new.

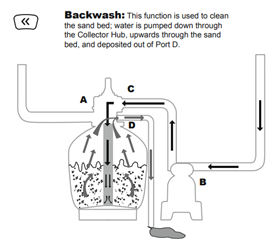

How to back flush:

- Turn power off (important, should not run the pump dry, will cause damage to pump)

- Close Port A using cap (switch from Port D to Port A basically)

- Attach hose to Port D

- Put the control valve to backwash position (<< symbol)

- Turn pump on until water turns clear (or around 3-5 mins)

- Turn pump off once water turns clear

- Remove old sand and refill, or rinse existing sand (water droplet symbol – rinse for 1 min)

- Once complete, remove cap from Port A and apply to Port D

Step 1 – Is the filter dirty?

If this is the case please perform back wash and rising procedure.

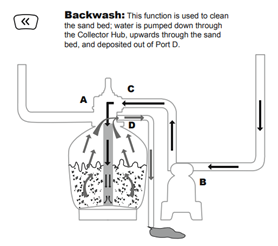

How to back flush:

- Turn power off (important, should not run the pump dry, will cause damage to pump)

- Close Port A using cap (switch from Port D to Port A basically)

- Attach hose to Port D

- Put the control valve to backwash position (<< symbol)

- Turn pump on until water turns clear (or around 3-5 mins)

- Turn pump off once water turns clear

- Remove old sand and refill, or rinse existing sand (water droplet symbol – rinse for 1 min)

- Once complete, remove cap from Port A and apply to Port D

Step 2 – Has the sand bed calcified?

This is rare to happen as long as you are regularly rinsing the sand/backwashing the pump. It means that the sand clumps together and forms hard rocks so it can’t be filtered correctly. We recommend inspecting the sand and change if required.

Step 3 – Insufficient backwash

If after 3-5 minutes after the backwash procedure the water is still not running clear, repeat the process again. If you are struggling to get the water to run clear we recommend changing the sand all together.

Step 4 – Check if the pressure gauge is broken.

Step 1 – Check if the washer is in the correct place on the connectors

If they are in the incorrect place amend this so they are. Check if this resolved the problem.

Step 2 – Check if the hoses are loose

If they are we recommend tightening up the hoses and check if this resolved the issue.

Step 1 – Is the filter dirty?

If it is we recommend completing the back flush procedure.

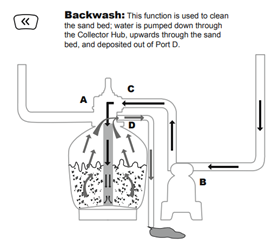

How to back flush:

- Turn power off (important, should not run the pump dry, will cause damage to pump)

- Close Port A using cap (switch from Port D to Port A basically)

- Attach hose to Port D

- Put the control valve to backwash position (<< symbol)

- Turn pump on until water turns clear (or around 3-5 mins)

- Turn pump off once water turns clear

- Remove old sand and refill, or rinse existing sand (water droplet symbol – rinse for 1 min)

- Once complete, remove cap from Port A and apply to Port D

Step 2 – Check if the control valve is set to filter function

The control valve will need to be set to the filter function to stop the warning sign bleeping.

Step 3 – Check if the hoses are broken

Step 4 – Is there a water flow?

Go through this checklist guide:

- Stopper plugs removed

- Control valve set to closed

- Strainer blocked

If this checklist does not resolve the problem the pump will need replacing. Replacements can be purchased here.

If you need any further assistance please contact our Customer Care team below.